Power and Control, PMC 9

The PMC 9 CNC is available as a complete turnkey solution. Our customers machine's often have specific physical requirements that require custom electrical enclosures and/or operator pendant. Other machines might have complex software cycles or a complicated user interface. The PMC 9's software can be customized to run any machine and imitate almost any user interface.

PMC 9 Hardware

MOTION CONTROL (MC82)

The PMC 9 is driven by the Motion Control 82 (MC82). The MC82 is the connection between the user interface, servo amplifiers and I/O modules. The connect from the PC to the MC82 is ethernet. The connection to the servo amplifiers is fiber optic, eliminating noise interference. The interface to the I/O modules is also over fiber optic cables. The MC82 also has RS232 communication.

SERVO AMPLIFIER (SD2)

The drive system SD2 is a flexible solution that permits quick and easy adaptation to the individual case of application – regardless of whether linear motors, rotary servo motors or motor-driven manufacturing spindles are operated. With SD2 you can implement applications with and without a speed sensor up to 180,000 rpm (3,000 Hz). Universal motor encoder evaluations and various options for the connection of the higher-ranking control are additional features to optimize multi-axis application.

SERVO AMPLIFIER (SD2S)

Powerful, flexible, low cost – these words describe the drive amplifier SD2S by SIEB & MEYER. The compact dimensions allow space-saving design of the switch cabinet. Linear motors, rotary servo motors, high-pole torque motors as well as synchronous/asynchronous tool spindles with or without sensor can be driven by SD2S. The SD2S is connected via the bus system SERVOLINK 4. The fiber optic connection ensures a noise free connection between the CNC control and the drive amplifiers.

INPUTS / OUTPUTS (I/O LINK)

General purpose digital I/O board with up to 64 points of I/O at 24VDC on a single board. Other modules have +/- 10VDC analog inputs and outputs. The connection the MC82 board is fiber optic, eliminating interference and ensuring a a high speed data transfer. Boards are mounted on DIN rail and include each I/O point has an LED for simplified troubleshooting. If the PMC 9 is being retrofitted to a previous control system, relays can be used to convert the I/O to 120VAC or to provide dry contacts for a separate control.

INDUSTRIAL PC

Compact industrial PC with upto 8GB of RAM and 128 GB of solid state storage, running a 6th generation intel i3 skylake processor. The Windows 7 operating systems allows for familiarity on the shop network for data collection, centralize part program storage, or system back. A wired or wireless internet connection to the control allows for TeamViewer remote suuport.

OPERATOR PENDANT

The standard operator's pendant has a touchscreen monitor. An optional wet/dust proof industrial keyboard with pointing device can also be added to the machine if it is required. A handheld pendant allows the operator greater freedom for program setup.

SERVO MOTOR

Compact and powerful servo motors. Available in multiple frame sizes, power ratings, and connectors.

Multiple feedback options available.

Resolver : Cost effective but loses position when the machine is powered off.

Multi-Turn Absolute Encoder (EnDat2) : Never loses position even when the machine is powered off

PMC 9 Software

EXECUTIVE SOFTWARE

Running under Windows, the PMC 9 has a user-friendly interface with touch screen, pull-down menus. Part program files can be input from any source standard to a PC (e.g USB device, local area network, CD ROM, floppy disk).

MOTION CONTROL

The motion control software runs on the MC84 board, providing high speed capability in time-critical functions. Up to six interpolated axes and six auxiliary axes are possible with the standard system. Additional configurations are available by request. Built-in servo tuning software simplifies the tuning process.

PROGRAMMABLE MACHINE INTERFACE (PMI))

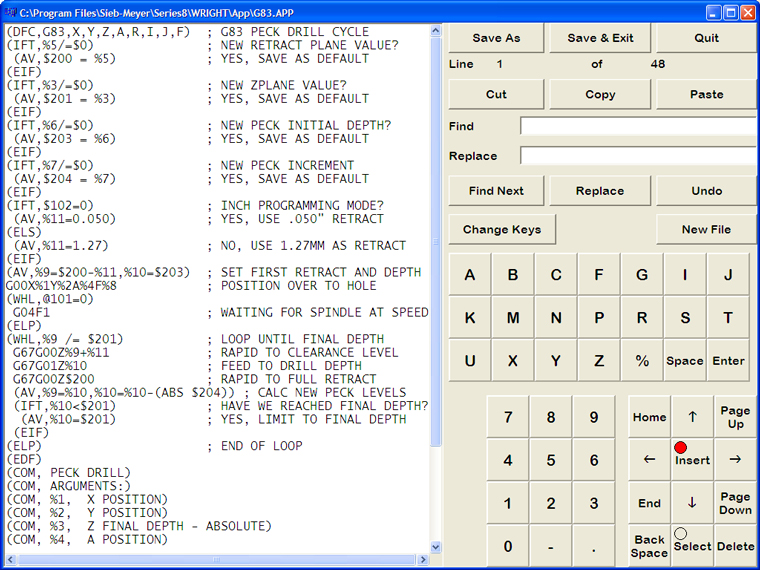

A powerful text-based language allows customization of the control interface using tools supplied with every PMC 9. PMI controls all the machine I/O, auxiliary axes, and cycle control of the machine as well as creating and handling of operator touch buttons. A real-time debugger provides a powerful tool to troubleshoot the machine. Click this title to see a section of PMI code and the real time debug displays.

ADVANCED PROGRAMMING PACKAGE

Parametric programming, subroutines, and canned cycles are all provided for under the APP programming system. To the right is a sample of an APP program for the G83 peck drilling cycle.

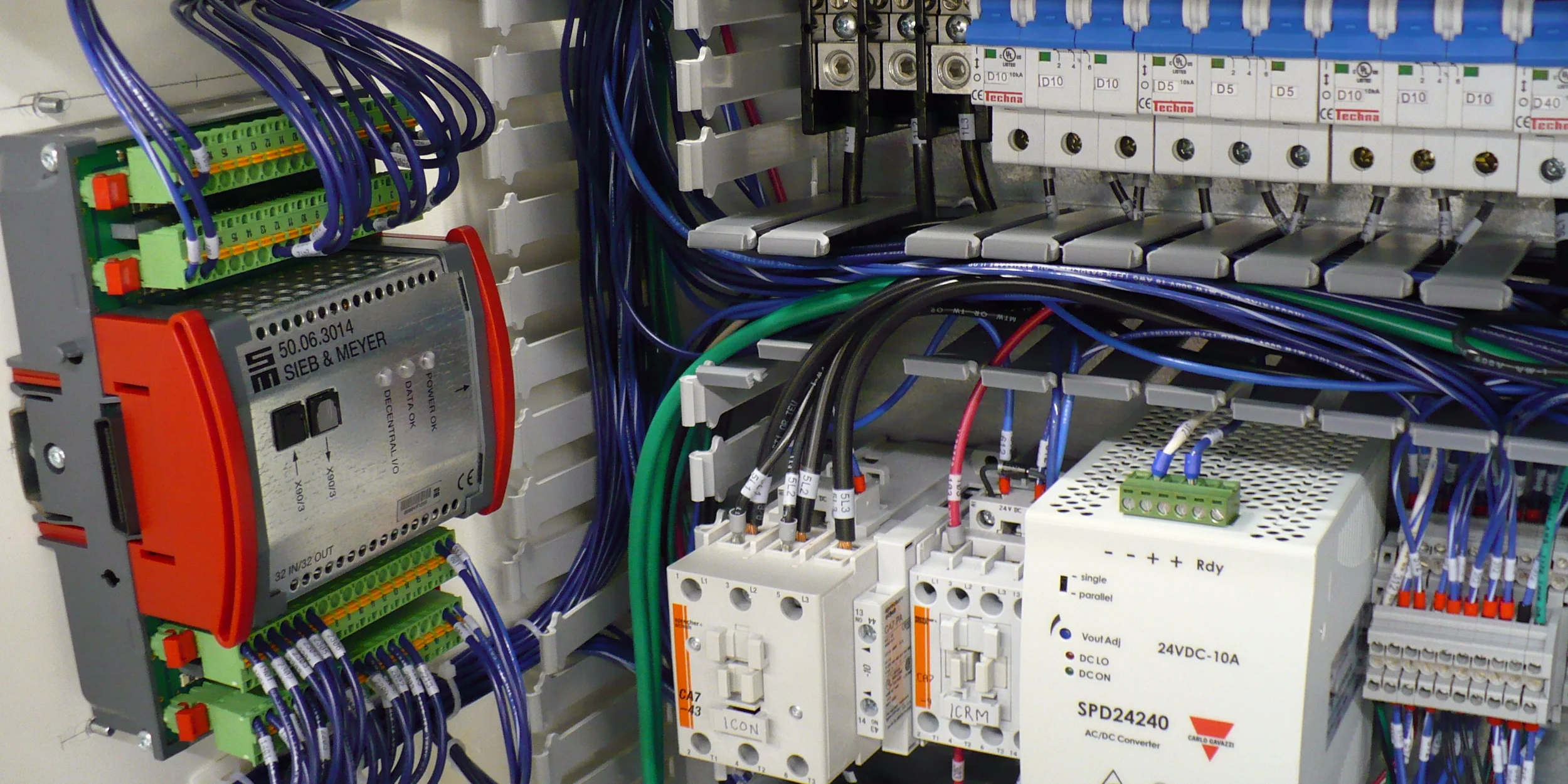

PMC 9 Complete Turnkey Solution

Below is an example of a 2 axis angle head grinder electrical enclosure.

Electrical Enclosure Components

Electrical Enclosure

Sub Panel

Cabinet Light

Electrical Disconnect

Transformer

Heat Exchanger

Circuit Breaker / Fuse

Auxiliary Motor Starter & Overload

Control Relay

DC Power Supply

Uninterrupted Power Supply

Motion Control Board

I/O Board

Servo Motor

Auxiliary Motor

Servo Amplifier

Servo Power Supply

Servo Motor Cable

Variable Frequency Drive

Current Transducer

Terminal Block

Distribution Block

External Connector

Current Load Sensor

Operator Pendant / Station Components

Pushbutton

Switch

Potentiometer

Industrial Touchscreen

Industrial Keyboard

Industrial PC

Light Tower

Handheld Pendant

Auxiliary Operator Stations

Pushbutton

Switch

Potentiometer

Industrial Touchscreen

Industrial Keyboard

Light Tower

Documentation

Control Manual

Electrical Schematics

Bill of Materials